Custom Machine Design & Automation Solutions

At CAD Work Engineering, we specialize in machine design and automation solutions that help industries improve efficiency and reduce manual labor. Our expert team handles everything from conceptualization to final production, ensuring that each machine is tailored to meet your unique business needs.

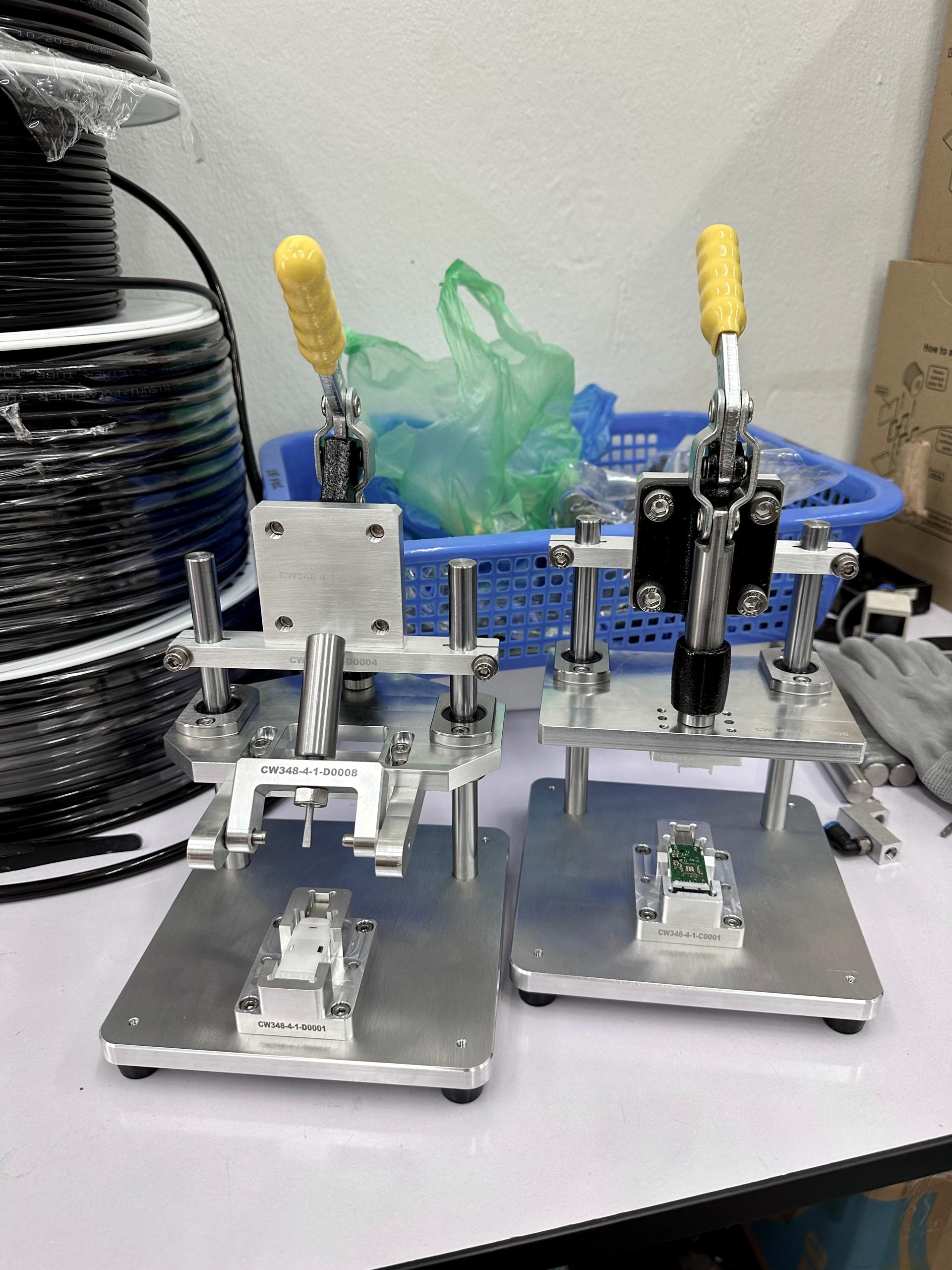

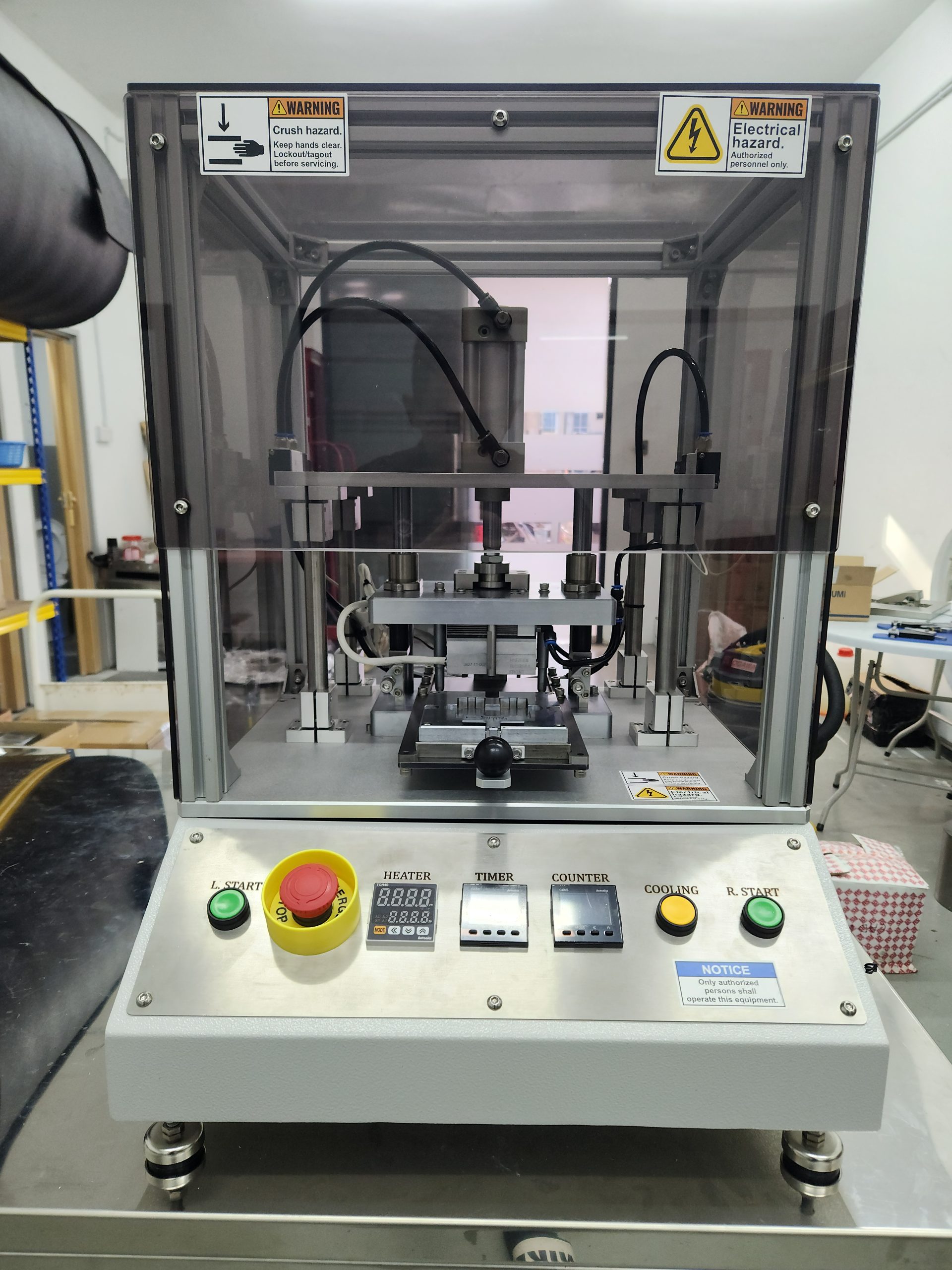

Our Machine Design Process

- Concept Development: Crafting the blueprint of your machine solution, ensuring it aligns with your operational needs.

- Detailed Design: Refining the concept into a functional and manufacturable design.

- Prototype & Testing: Creating and testing prototypes to validate the design and ensure it meets your expectations.

- Production & Manufacturing: Bringing the final design to life with precision and reliability, ready for your production line.

Robotic System Design in Malaysia

At CAD Work Engineering, we offer state-of-the-art robotic system design and industrial automation solutions tailored to the needs of businesses in Malaysia. Our robotic solutions help companies enhance efficiency, improve safety, and achieve faster returns on investment. With our expertise, we integrate cutting-edge robotics into various industries, including manufacturing, logistics, and electronics.

Our Robotic Automation Capabilities:

- Precision Assembly Robots: High-speed, highly accurate robots designed for complex product assembly in industries like automotive and electronics.

- Material Handling & Palletizing: Robotic arms and Automated Guided Vehicles (AGVs) that streamline loading, unloading, and packaging processes.

- Welding & Fabrication Robots: Automated welding solutions offering consistent, high-quality results for industries like metalworking and heavy machinery.

- Machine Tending: Autonomous robots that manage CNC machines, injection molding systems, and more, ensuring continuous operation without manual intervention.

By incorporating robotic systems into your production line, we help you boost productivity, reduce costs, and maintain high standards of quality and safety.

AI Machine Vision for Industrial Automation

Applications of AI Machine Vision:

- Defect Detection: Automatically identify surface flaws, cracks, and irregularities in real-time to ensure product quality.

- Assembly Verification: Verify that each product meets design specifications and safety requirements.

- Dimensional Measurement: Perform non-contact, high-precision measurements during production to maintain consistency.

- Quality Control & Traceability: Track products throughout the manufacturing process to ensure compliance and traceability.

With AI machine vision, manufacturers can achieve smarter, more reliable production processes that minimize errors and maximize operational efficiency.

Why Choose CAD Work Engineering?

- End-to-End Service: We offer comprehensive support from concept development through prototype testing and full-scale production.

- Tailored Solutions: Our team works closely with you to create custom robotic systems and machine designs that perfectly align with your industry needs.

- Future-Ready Technology: We integrate AI and robotics to help businesses stay ahead of the curve in automation and innovation.

If you’re ready to explore how our robotic systems and AI machine vision solutions can transform your manufacturing operations, visit our Products Page or Contact Us for a consultation.

FAQ: Custom Machine Design & Robotic Systems

What industries benefit from your robotic systems?

Our robotic systems are ideal for manufacturing, logistics, automotive, and electronics, helping businesses streamline operations like assembly, handling, welding, and packaging.

How long does it take to implement a custom robotic system?

Typically, the design and implementation process takes 3 to 6 months, depending on the project complexity, from initial design to final deployment.

What is AI machine vision, and how does it improve manufacturing?

AI machine vision automates visual inspection, detecting defects, verifying assemblies, and measuring dimensions. It improves quality control and enhances efficiency by reducing human error.

Do you offer post-installation support?

Yes, we provide ongoing maintenance, training, and troubleshooting to ensure your systems run smoothly after installation.

Can your robotic systems integrate with existing machinery?

Yes, we can integrate our robotic systems with your current machines, like CNCs and injection molding systems, to enhance productivity without replacing existing equipment.

Are your solutions scalable?

Yes, our systems are scalable, designed to grow with your business. We can expand or adapt them as your production needs increase.

What are the benefits of using robotic systems and AI machine vision in Malaysia?

These solutions boost efficiency, product quality, and safety, while reducing labor costs and human error, helping businesses in Malaysia stay competitive.

Do you provide a warranty for your systems?

Yes, we offer a warranty on all robotic systems and provide after-sales support to ensure long-term performance.

How can I get a quote?

Request a quote by contacting us with your project details, and we’ll provide a customized proposal.

Can your AI machine vision systems work across multiple production lines or sites?

Yes, our AI vision systems can be scaled to work across multiple production lines or sites, ensuring consistent quality control and monitoring.