In Malaysia’s growing manufacturing and assembly sectors, automation tools play a crucial role in increasing productivity and maintaining quality. Among these tools, screwing machines stand out as essential for streamlined, consistent fastening tasks. Whether in electronics, automotive, or furniture production, a high-quality screwing machine improves efficiency, accuracy, and operator safety.

These machines not only increase production capacity but also play a key role in meeting international quality standards and reducing human errors in repetitive tasks. With Malaysia’s push toward Industry 4.0 and smart manufacturing, screwing machines are rapidly becoming a standard investment for both SMEs and large industrial facilities.

What Is a Screwing Machine?

A screwing machine is an automated or semi-automated device used to insert and tighten screws during manufacturing or assembly processes. These machines enhance speed, accuracy, and consistency while reducing manual effort and repetitive strain injuries.

They can vary widely in design—from basic handheld tools to advanced robotic systems—depending on the required torque, product size, and production throughput. The integration of control systems and sensors allows for real-time monitoring, improving the quality and reliability of assembly.

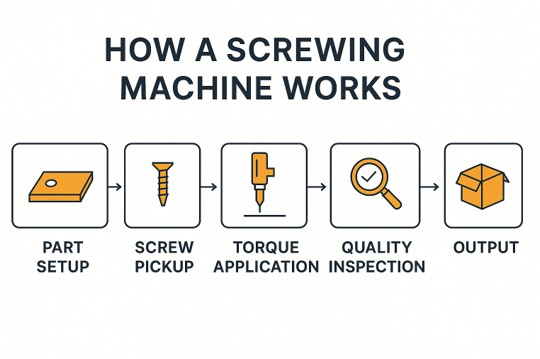

Below is a simple process flow of how a typical screwing machine operates:

Figure: Process flow from part setup to output in an automated screwing system.

Types of Screwing Machines Available in Malaysia

1. Handheld Electric Screwdrivers

- Ideal for light assembly tasks

- Torque-controlled to prevent over-tightening

- Ergonomic and portable, suitable for mobile or small workstations

- Commonly used in electronics repair and small appliance manufacturing

2. Semi-Automatic Screwdrivers

- Suitable for mid-volume production environments

- Integrated screw feeders reduce the need for manual loading

- Often used in production cells and modular workbenches

- Balances speed and affordability

3. Fully Automatic Screwing Systems

- Best suited for continuous, high-volume production lines

- Offers integration with conveyor belts and robotic arms

- Supports automatic screw feeding, torque control, and cycle time tracking

- Ensures consistent assembly quality across thousands of units

4. Pneumatic Screwdrivers

- Powered by compressed air, ideal for high-speed operations

- Less sensitive to voltage fluctuations or electric safety regulations

- Preferred in heavy-duty environments such as automotive component assembly

5. Robotic Screw Fastening Systems

- Offers unmatched precision and adaptability

- Equipped with AI, vision-guided alignment, and torque feedback

- Capable of working across multiple axes and adapting to complex geometries

- Used in high-tech industries like aerospace, medical devices, and electronics

Benefits of Using Screwing Machines in Malaysian Industries

- Increased Production Speed: Automation significantly reduces cycle times and manual handling delays, allowing manufacturers to scale efficiently.

- Enhanced Accuracy: Torque sensors and programmable logic control (PLC) ensure each screw is inserted with the exact force required, reducing product rejections.

- Improved Operator Safety: Minimizes the risk of repetitive strain injuries and fatigue, especially in long production shifts.

- Lower Operational Costs: While initial investment may be higher, ROI is quickly realized through reduced labour, higher output, and lower scrap rates.

- Traceability and Quality Control: Data logging features help manufacturers meet ISO and customer-specific quality documentation requirements.

Industries That Rely on Screwing Machines in Malaysia

- Electronics Manufacturing: Screwing machines are crucial for assembling circuit boards, casings, and electronic components that demand precision and anti-static safety measures.

- Automotive Industry: From dashboards and control units to engine bay assemblies, automated screwdrivers ensure tight tolerances and compliance with safety standards.

- Furniture Production: Modular and flat-pack furniture producers rely on semi-automatic and robotic screw systems for consistent joint integrity and time efficiency.

- Medical Devices: Devices like insulin pumps, diagnostic equipment, and monitors require tight quality control—made possible with torque-monitored fastening systems.

Choosing the Right Screwing Machine in Malaysia

Selecting the ideal screwing solution involves more than just budget — it’s about operational fit. Here are key criteria to guide your decision:

- Torque Requirements: Different materials and screw sizes need specific torque values to avoid product damage or weak fastening.

- Production Volume: High-throughput environments benefit most from fully automated or robotic systems.

- Material Compatibility: Soft materials like plastics require adjustable torque settings to prevent cracking or misalignment.

- Automation Goals: Consider if integration with your MES (Manufacturing Execution System) or conveyor systems is necessary.

- Service & Support: Partner with a vendor offering training, spare parts, and technical support for ongoing reliability.

Where to Find Quality Screwing Machines in Malaysia

Cad Work Engineering is offering a wide range of screwing machines and assembly systems:

- Tailored consultation based on your production needs

- Installation, commissioning, and staff training

- Preventive maintenance and emergency support

- Product upgrades to scale as your business grows

With expert consultation, installation, and after-sales service, Cad Work Engineering ensures that your production line operates efficiently and reliably.

Looking for a srewing machine supplier in Malaysia? Contact us to find a system that fits your production needs.

📞 Contact Us Today:

Frequently Asked Questions (FAQ) About Screwing Machine in Malaysia

1. What types of screws can be used with automated screwing machines?

Most screwing machines can accommodate a variety of screws, including self-tapping, machine, and micro screws. Always verify compatibility with your supplier.

2. What is torque feedback in a screwing machine?

Torque feedback is a feature that monitors and controls the torque applied during screwing, ensuring accuracy and preventing over-tightening or stripping.

3. Is it possible to integrate vision systems with screwing machines?

Yes, advanced screwing machines can be equipped with vision systems to guide screw positioning and perform quality inspections in real-time.

4. How do I select the right torque setting for my application?

The optimal torque depends on screw size, thread type, and material. Refer to manufacturer specifications or consult your equipment supplier for precise calibration.

5. Can screwing machines handle multi-axis assembly operations?

Certain high-end models support multi-axis screwdriving and robotic arms to perform complex assembly operations across different angles and surfaces.

6. What is the typical lifespan of a screwing machine?

With proper maintenance, screwing machines can last several years. Usage frequency, environment, and servicing practices affect longevity.

Conclusion

Screwing machines are essential tools in Malaysia’s journey toward modern, automated manufacturing. They offer unmatched precision, efficiency, and consistency — making them a worthy investment for industries aiming to improve product quality and output.

Disclaimer:

This article is intended for general informational purposes only and may not represent the full range of services offered by CAD Work Engineering Sdn. Bhd. For tailored advice specific to your needs, please consult a qualified professional or contact us directly. While we make every effort to ensure the accuracy and completeness of the information provided, CAD Work Engineering Sdn. Bhd. makes no guarantees and accepts no responsibility for any errors or omissions.