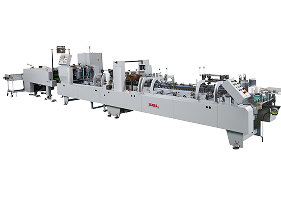

Key Features of Our Glueing Machine

- Precise adhesive control for consistent results

- Adjustable speed and glue flow settings

- Compatible with various types of adhesives

- Easy to operate and maintain

- Suitable for automated production lines

Common Applications

- Packaging assembly lines

- Electronics and circuit board manufacturing

- Woodworking and furniture production

- Automotive parts assembly

FAQ About Glueing Machine in Malaysia

What is a glueing machine used for?

A glueing machine is used to apply adhesives quickly and evenly on products during assembly. It helps speed up the bonding process and ensures consistent quality in manufacturing.

What types of adhesives can be used with a glueing machine?

Most glueing machines can handle various adhesives like hot melt glue, water-based glue, PUR, or epoxy, depending on the material and application.

Which industries commonly use glueing machines?

Glueing machines are widely used in packaging, electronics, furniture, automotive, and other industries that need fast and reliable bonding.

Can the glueing machine be customized for different production lines?

Yes, our glueing machines can be customized to fit your specific workflow, product size, glue type, and automation level.

What are the benefits of using an automated glueing system?

Automated glueing improves speed, reduces glue waste, enhances bonding accuracy, and lowers labor costs by minimizing manual work.

Need a Reliable Glueing Machine in Malaysia?

Contact our team today for a free consultation. Let’s build the right automation solution for your production line.