Key Features of Our Inspection Machines

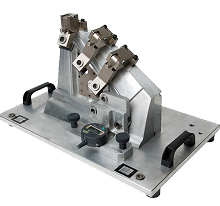

1. High Precision Detection

Detects even tiny defects or inconsistencies with accurate measurement tools.

2. AI & Vision System Integration

Equipped with machine vision or sensor technology for fast and reliable inspection.

3. Real-Time Feedback

Provides instant data and alerts for out-of-spec products, helping reduce waste.

4. Customizable Design

Can be tailored to suit different product sizes, shapes, and inspection criteria.

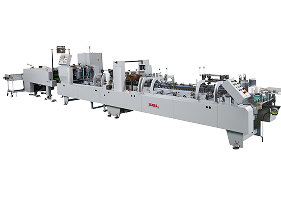

5. Easy Integration

Works seamlessly with automated production lines or manual workflows.

6. User-Friendly Interface

Simple control panel and data output system for efficient operation.

Common Applications of Inspection Machines

- Electronics Industry: For checking PCB boards, solder joints, or component placement.

- Automotive Manufacturing: To inspect engine parts, fittings, or welded joints.

- Medical Devices: For visual inspection of syringes, tubes, or plastic moulded parts.

- Plastic & Packaging: Detects label misalignment, seal defects, or foreign particles.

- Food & Beverage: Used to ensure packaging accuracy and detect contamination.

FAQ About Inspection Machines

What is an inspection machine used for?

It’s used to check products for defects, errors, or missing components before they move to the next step or get shipped out.

What types of products can be inspected?

Almost anything — from small electronics and medical parts to automotive components and plastic packaging.

How does a vision-based inspection machine work?

It uses cameras and software (sometimes with AI) to scan products and compare them against preset standards.

Can the machine be customized for different product types?

Yes, our machines are fully customizable to suit your production line, product size, and inspection needs.

What maintenance is required to ensure long-term performance of an inspection machine?

Regular cleaning of lenses/sensors, software updates, and checking calibration will keep the machine running accurately and efficiently.

How accurate are inspection machines compared to manual checking?

Most automated inspection machines offer higher precision and consistency than manual inspection, especially for repetitive tasks.

What’s the benefit of using automated inspection over manual checks?

Automated systems are faster, more accurate, reduce human error, and can work 24/7 without fatigue.

What is the ROI of investing in an inspection machine?

Typically, manufacturers see cost savings through reduced product recalls, fewer defects, and faster production times within months of use.